ISTTOK - Wiki

IST Tokamak - ISTTOK

Índice

Description

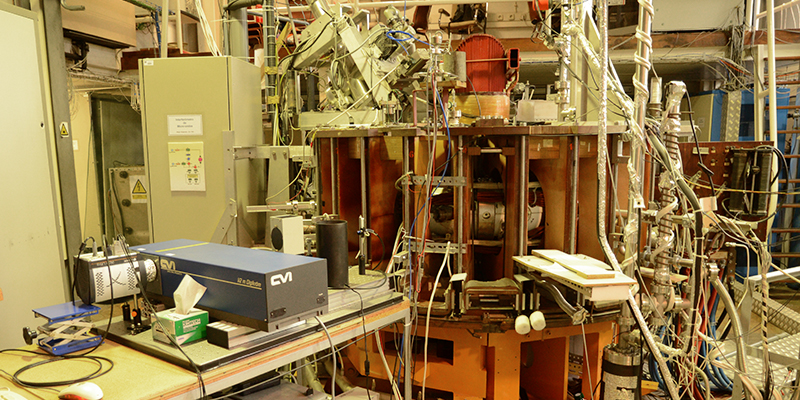

The ISTTOK Tokamak ("Instituto Superior Técnico TOKamak") is a research fusion device located at Instituto Superior Técnico in Lisbon, Portugal.

The toroidal vacuum vessel has a large aspect ratio and is surrounded by a copper shell. Plasma heating is purely ohmic, provided by an iron core transformer, and the plasma cross-section is circular, shaped by a full poloidal graphite limiter. The magnetic toroidal field relies on a set of 24 coils and an external poloidal field is driven by 4 sets of toroidal coils. ISTTOK was rebuilt in Lisbon from its predecessor TORTUR tokamak, which was de-commissioned by the Association EURATOM/FOM in 1988, using most of its original components (supporting structure, vacuum chamber, copper shell, transformer core and toroidal magnetic field coils).

Goals and research objectives

ISTTOK has been scientifically explored for:

- Edge plasma turbulence studies;

- Operation and control of alternating plasma current regimes;

- Testing of liquid metal limiter concepts;

- Development and upgrade of diagnostics;

and has also served as a test bed facility for new data acquisition concepts and hardware.

Theory contribution

The understanding of turbulent transport phenomena is of the utmost importance for both the performance and the reliable operation of future plasma fusion devices. The universality of physical aspects of the plasma edge on radically diverse tokamak devices (in terms of size, inner core performance and heating methods) renders small machines like ISTTOK as relevant for edge studies. As a small machine, ISTTOK is flexible in its operation, runs on low operation costs, has a short time scale for diagnostic implementation and is compatible with the use of electrostatic probes, one the most useful diagnostic to access edge plasma fluctuations. Present activities include:

- Contribution towards a better understanding of spontaneously generated large-scale sheared flows and its role in regulating plasma transport.

- Characterization and control of the SOL intermittent transport.

- Development of innovative electrostatic probe systems.

- Providing synergies between theory and experimental groups working on edge/SOL physics.

- Development of analytical tools required to process the massive experimental data obtained.

Diagnostics development

- A diagnostic based on 3 tomographic cameras was developed, adding to the multiple choice of diagnostics for real-time monitoring implementation in ISTTOK. The tomography diagnostic has been improved in its spacial resolution for enhanced emissivity reconstruction using analytical methods.

- A retarding electrostatic field cylindrical energy analyzer (CEA) was built and has gone through multiple developments, aiming at the measurement of the plasma potential in the core and its fluctuations.

Main achievements

AC operation

The iron core saturation limits the operation of ISTTOK in single pulse mode for about 35 ms. New control systems and power supplies for the toroidal electric field and for the external magnetic poloidal field were built, aiming at increasing the operation of ISTTOK to 1 s in AC mode. Within this line of research present activities include:

- Operation of the tokamak ISTTOK in a multi-cycle alternating plasma current regime, to obtain long duration discharges.

- Implementation of a real-time plasma control system and study of the control of long duration AC discharges in ISTTOK.

- Development of advanced gas feed control to improve reproducible and reliable plasmas with high performance.

- Testing of plasma facing materials including liquid metals.

Liquid metals as PFCs

One of the most challenging issues regarding the operation of a future fusion reactor is related to plasma-wall interaction. Solid materials exposed to fusion plasmas are known to suffer significant damage that reduces wall lifetime. Liquid metals have proven to be of relevance for PFC protection. Due to ISTTOK characteristics, its programme has also been focusing on testing liquid metals PFC´s and their properties:

- Development of a novel Liquid Metal Limiter based on micro-channel structures.

- Building and testing the new LML concept using gallium as liquid metal.

- Exposure of the gallium LML to ISTTOK plasmas.

- Studying the behaviour of the limiter surface temperature increase with liquid metal re-circulation.

Data acquisition and control

ISTTOK provides more than 100 acquisition channels, two spectrometers imaging systems and several I/O control channels, supported by a robust database with easy methods for retrieving information (supporting Matlab, Python, Mathematica ,C++, JAVA, etc).

By using MARTe and this infrastructure it was implemented a control system based on an optimized state-space model for real time control of the plasma current magnitude and centroid position retrieved by a twelve mirnov coils poloidal set.

ISTTOK uses as well numeric-integrated digital channels to determine the local magnetic field and by such approach calculate the better current profile in real-time.

Physical parameters

Nominal plasma parameters

Precedents

TORTUR

Tortur was a tokamak designed in Grenoble with an initial primary to secondary winding ratio of 1:1. It starts to operate in 1974 at the FOM institute at Nieuwegein on the Neederlands.

For the primary was used the stabilizing cooper-shell structure. A very high current had to be feed in this primary and short discharges were obtained (up to 8 ms). The vessel was a glass-quartz type. It's name origin was due to the acronym TORus for TURbulent heating. The underlying idea was to generate a suficient large current through the plasma to the limit were micro-instabilites will be excited enhancing the plasma resistivity and allowing further ohmic-heating.

TORTUR II

Tortur was not capable to diagnose properly the heated plasma and the high primary voltage needed posed severe insulation problems. In 1978 it undergoes a major upgrade. A new stainless steel 625 vessel was installed being divided in two C-sections and equiped with 33 ports of 35mm, constructed by Avica Equipment, England. Basically the vessel were made based on port structures welded together by a thin inconnel bellow of 0.15mm with an inner diameter of 200mm. Such thin metal structure allowed for a suficient fast penetration of the electric fiels used for the turbulent heating.

TORTUR III

By 1981 Tortur undergo again a vessel upgrade of the former one by the same manufacturer, assuming the actual design as in ISTTOK . A higher toroidal magnetic field was comissioned to improve confinement (up to 5T) in paralell with a structural reinforcement. Besides that it was equipped with a iron-core transformer yoke switchable in a 20:1 or 40:1 ratio, allowing to extend plasma discharges up to 50 ms. This pulse extension was possible as well by the instalation of a quadrupole for creating the necessary vertical and horizontal magnetic fields for plasma stability, centering the plasma in the chamber.

By then the copper-shell was used sollely for the fast turbulent heating by firing a 25uF and up to 20kV for a steep-rising heating pulse at any presetable time duplicating the current(30->60kA) for ~10us. This thecnic allowed up to 1keV plasmas.

Prior to the main discharges Tortur was "cleaned" by creating a glow discharge with the RF generator, heating the vessel up to 180ºC and producing small discharges with a low toroidal field (~50 mT) to outgas the vessel from impurities.

It is worth to mentioned that all aquisition systems was based on CAMAC boards (5 crates) controlled by a PDP 11/23 Digital Inc. mainframe computer (-1988) and all data from the transient recorders being backuped on tape.

ISTTOK@XX

After the commissioning in Portugal, Tortur became the IST TOKamak, ISTTOK. During XX century is was operated with two capacitors banks as it's predecessor and only with forward current. The main systems have been updated, namely the vacuum systems, power supplies, the plant control systems and data acquisition. Discharges were started based on a cold plasma generated by the TORTUR RF generator (1.7MHz) but due to the high noise have been soon replaced by an electron beam source (80 eV, tungsten filament) situated on the high field side close to the SOL. The hot plasma was started by the high voltage bank (1-5kV, 1mF, 2-3ms) and then an electrolytic bank (0.4F, 350V, 40-50ms) took over. With this electron gun to pre-ionize the gas it was not necessary anymore to use the high-voltage capacitor to disrupt the gas.

Main components

Innovative features

ISTTOK were since the beginning equipped with a tunnable toroidal field in view of adjusting the cyclotronic frequency to a desired value. This was quite uncommon in such class of tokamaks were the toroidal field was basically imposed either by a fixed transformer ratio from the grid or by using a capacitor bank. Conversely, due to the lack off available power in campus, toroidal field had to be limited to ~0.5T.

After a first exploitation phase with very similar Tortur parameters except for the toroidal field, ISTTOK@XXI became the first tokamak equipped with a switched IGBT primary circuit with a considerable larger capacitor bank (3.8F), allowing multiple AC discharges.

ISTTOK is one of the few fusion devices equipped with an heavy ion beam diagnostic.

List of main components

This section lists exhaustively ISTTOK main components which are referred in more detail on article ISTTOK main components

- Toroidal field

- Geometry

- Current supply

- Poloidal fields

- Geometry

- Power amplifiers

- Vessel

- Support structure

- Vacuum system

- Primary vacuum

- High vacuum

- Gas injection

- Background pressure

- Gas puffing

- Residual gas analyzer

- Gauges

- Broadband spectrometer

Diagnostics

The diagnostics systems in tokamaks usually serve two proposes: either to allow a proper control of the machine or being themselves the research object. The former constitutes the "technical diagnostics" allowing (i) a correct machine's operation, (ii) estimation of the discharge performance, (iii) the usage in the real time control loop and (iv) serve some interlock security services. The "scientific diagnostics" constitute the research object normally are not yet ready to be used without a previous data validation from the involved team. Those ones can be as well oriented to study just a particular plasma behavior or academic activity, without the future objective to serve as a regular diagnostic. Some of the diagnostics can be inoperative for a given time according to data acquisition limitations or maintenance.

List of main diagnostics

Please refer to a more detail article on ISTTOK Diagnostics.

Technical diagnostics

- Magnetics

- Halpha monitors

- Electron Cyclotron Emission

- Soft X-rays

- Multifilter electron temperature diagnostic

- Bolometry

- Broad band spectroscopy

- Residual gas analyzer

- Fast camera

- Interferometry

- Vacuum gauges

- Pyrometers

- Tomography

- Heavy ion beam

Scientific diagnostics

- Langmuir Probes

- Thomson Scattering (Presently in operation at TCA-BR)

- Helium injection

- Reverse field analyzer

- Reflectometry (Presently in operation at TCA-BR)

- Heavy Ion Beam Probe

Training and Education

ISTTOK as served as a facility were several PhD and master thesis occorres. Students can also apply for training courses such as the Tokamak Engineering and Operation